Mochini oa polasetiki oa PE Pipe Extruder

Tlhaloso

PE extruder e sebelisoa ho polyethylene extrusion ho ntša PE, polyolefin le thermoplastics tse ling.

Mochini oa polyethylene extrusion o ka sebetsana le mefuta eohle ea lihlahisoa tsa polasetiki ka mochini o thusang o amehang, joalo ka filimi, pipi, bar, poleiti, khoele, ribone, lera le sireletsang la thapo, lihlahisoa tse se nang letho joalo-joalo.

Mochini oa polythene extruder o tsoetse pele mme matla a tlhahiso a phahame. Hdpe ldpe extruder plasticization e ntle, 'me tšebeliso ea matla ea mochini oa ldpe extruder e tlase. E sebelisa sefahleho sa leino le thata bakeng sa phetisetso, e na le monyetla oa lerata le tlase, ts'ebetso e boreleli, mojaro o moholo, tšebeliso ea nako e telele joalo-joalo.

Kopo

EXTRUSION EA PEPI ea metsi le ea Khase.

PE extruder e sebelisoa haholo-holo ho polyethylene extrusion bakeng sa pipe, sheet, bar le lihlahisoa tse ling tsa polasetiki tse tsoang thepa ea PE e nang le mefuta e fapaneng ea mochine le tlaase.

Bakeng sa SJ serial screw extruder, bophara ba screw bo tloha ho 20 ho isa ho 200mm, 'me screw L/D ke 10-40. U ka khetha mofuta oa extruder ho ea ka lihlahisoa tsa hau, litlhaloso le bokhoni.

Sistimi ea phepelo e sebelisa YASKAWA .mme e kholo e amohela likarolo tse tsoang kantle ho naha tsa NSK tsa Japane, extruder e na le boleng bo botle ba chelete.

Molemo oa Litlhōlisano

Tšepahala ea khokahanyo: Sisteme ea phala ea polyethylene e hokahaneng pakeng tsa tšebeliso ea hotmelt ea motlakase, matla a kopaneng a phahame ho feta matla a 'mele oa phala.

Khanyetso e ntle ea mocheso o tlase: brittleness ea mocheso o tlase oa polyethylene mocheso o tlase o ka ba ka har'a mocheso oa subzero 60 ho isa ho 60 degrees Celsius e bolokehile hore e ka sebelisoa. Kaho nakong ea mariha, ka lebaka la lisebelisoa, ho hanyetsa tšusumetso ho molemo, ho kenngoa ha tube ho ke ke ha etsahala.

Khanyetso e ntle ea khatello ea maikutlo: HDPE e na le kutlo e tlase ea lekhalo, matla a phahameng a ho kuta le bokhoni bo botle ba ho thibela ho qaleha, ho hanyetsa ts'ebetso ea khatello ea tikoloho le eona e hlahelletse haholo.

Ho hanyetsa hantle lik'hemik'hale: Pipe ea HDPE e ka hanyetsa mefuta e fapaneng ea mecha ea litaba ea lik'hemik'hale, ho bola, lik'hemik'hale tse teng mobung li ke ke tsa baka tšenyo leha e le efe ea lipeipi. Polyethylene ke Insulator ea Motlakase, e ke ke ea etsahala ho bola, mafome kapa ntho ea electrochemical corrosion; Ho feta moo, e ke ke ea khothaletsa algae, libaktheria kapa kholo ea fungal.

Anti botsofali, bophelo bo bolelele: e nang le 2% ho 2.5% ea kabo junifomo ea carbon black ka polyethylene phala e ka ba polokelo ea ka ntle kapa tšebeliso ea lilemo tse 50, e ke ke ea ba tlas'a ultraviolet mahlaseli a kotsi.

Khanyetso ea abrasion: Pipe ea HDPE le liteko tsa papiso li bonts'itse ho hanyetsa ha phala ea tšepe, phala ea HDPE makhetlo a 4 ho hanyetsa phala ea tšepe. Sebakeng sa lipalangoang tsa seretse, ha se bapisoa le phala ea tšepe, pipe ea HDPE e na le khanyetso e ntle ea ho apara, e bolelang hore pipe ea HDPE e na le bophelo bo bolelele le moruo o molemo.

Molemo o feto-fetohang: Peipi ea HDPE e tenyetseha e etsa hore ho be bonolo ho kobeha, e sebetsa ka ho fetola liphaephe e ka ba tsela ea ho qoba litšitiso ho ea, 'me hangata, li-fittings tsa liphaephe tse tenyetsehang ho fokotsa tšebeliso le litšenyehelo tse tlase tsa ho kenya.

Khanyetso ea phallo: Pipe ea HDPE e na le bokaholimo bo boreleli bo kahare, coefficient ea Manning ea 0.009. Ts'ebetso e boreleli ebile e sa khomarele e netefatsa hore phala ea HDPE e na le matla a phetisetso ea lipeipi tsa setso, empa hape e fokotsa tahlehelo ea khatello ea liphaephe le tšebeliso ea metsi.

Lintlha tsa Tekheniki

|

Mohlala | L/D | Bokhoni(kg/h) | Lebelo la ho potoloha (rpm) | Matla a motlakase(KW) | Bophahamo bo bohareng(mm) |

| SJ25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ45 | 25-33/1 | 80-100 | 20-150 | 7.5-22 | 1000 |

| SJ65 | 25-33/1 | 150-180 | 20-150 | 55 | 1000 |

| SJ75 | 25-33/1 | 300-350 | 20-150 | 110 | 1100 |

| SJ90 | 25-33/1 | 480-550 | 20-120 | 185 | 1000-1100 |

| SJ120 | 25-33/1 | 700-880 | 20-90 | 280 | 1000-1250 |

| SJ150 | 25-33/1 | 1000-1300 | 20-75 | 355 | 1000-1300 |

Single Screw Extruder

Ho latela karo-karolelano ea 33: 1 L/D bakeng sa moralo oa screw, re thehile karolelano ea 38: 1 L/D. Ha ho bapisoa le karo-karolelano ea 33: 1, karolelano ea 38: 1 e na le monyetla oa ho etsa polasetiki ea 100%, e eketsa matla a tlhahiso ka 30%, e fokotsa tšebeliso ea matla ho fihla ho 30% mme e fihlella ts'ebetso e batlang e lekana.

Simens Touch Screen le PLC

Etsa kopo ea lenaneo le ntlafalitsoeng ke k'hamphani ea rona, u be le Senyesemane kapa lipuo tse ling ho kenya letsoho tsamaisong.

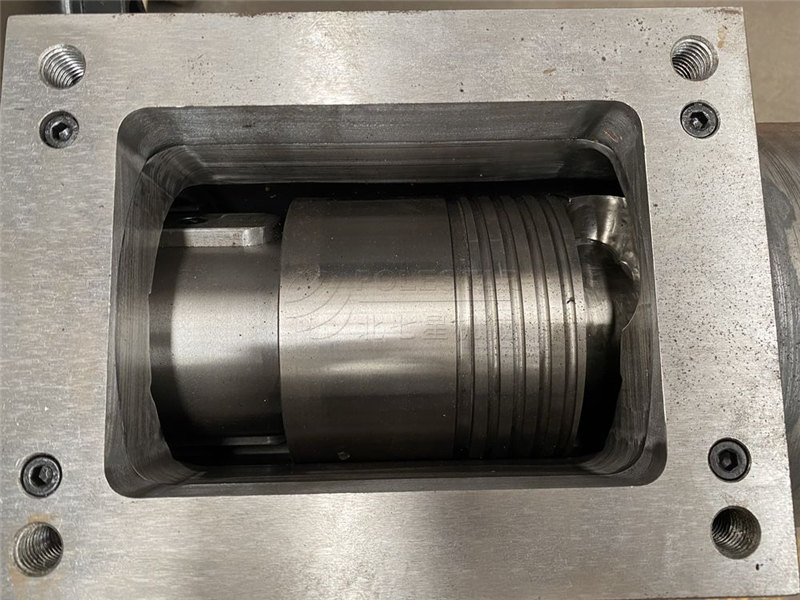

Moqapi o Khethehileng oa Screw

Screw e entsoe ka sebopeho se ikhethileng, ho netefatsa hore polasetiki e ntle le ho kopanya. Lintho tse sa qhibilihisitsoeng li ke ke tsa feta karolo ena ea screw, e ntle ea polasetiki ea extrusion screw.

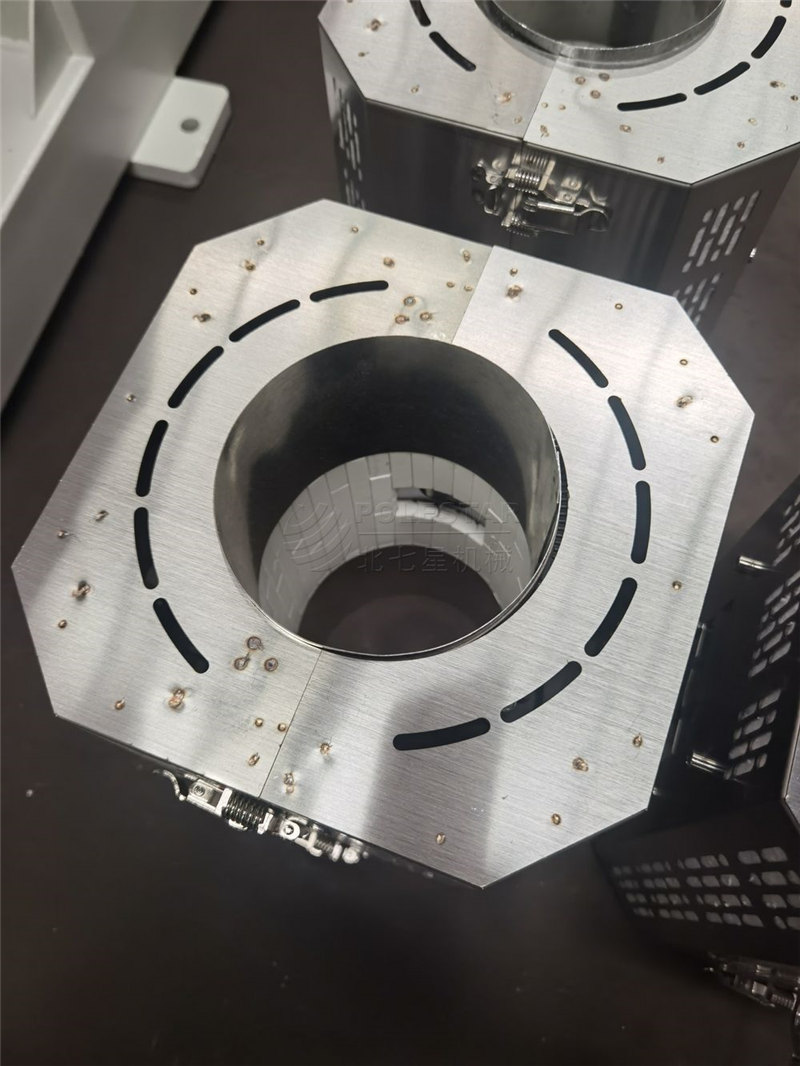

Sebopeho sa Spiral sa Barrel

Ho fepa karolo ea barrel ho sebelisa sebopeho sa spiral, ho etsa bonnete ba hore phepo ea lintho tse bonahalang e tsitsitse le ho eketsa matla a ho fepa.

Air Cooled Ceramic Heater

Ceramic heater e netefatsa bophelo bo bolelele ba mosebetsi. Moralo ona ke ho eketsa sebaka seo heater e kopanang le moea. Ho ba le phello e ntle ea ho pholisa moea.

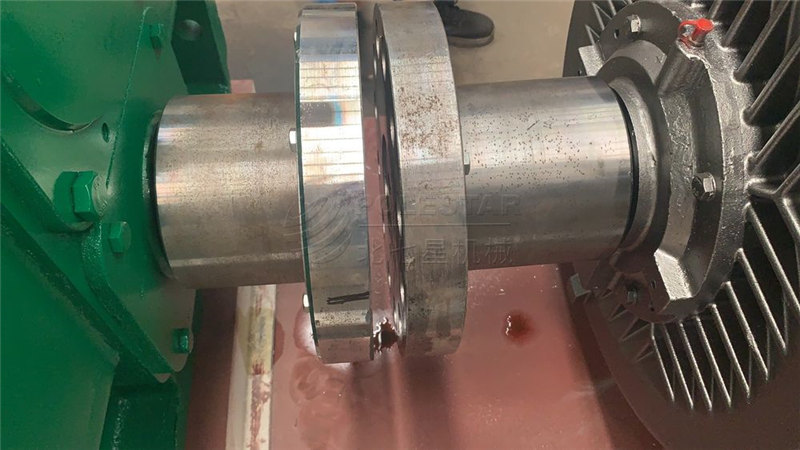

Gearbox ea boleng bo holimo

Ho nepahala ha gear ho lokela ho netefatsoa ka grade 5-6 le lerata le tlase ka tlase ho 75dB. Sebopeho se kopaneng empa se na le torque e phahameng.

Lihlopha tsa lihlahisoa

U batla ho kenya Sky ho Moralo oa hau?

Ikopanye le rona kajeno bakeng sa lipuisano tsa moralo.