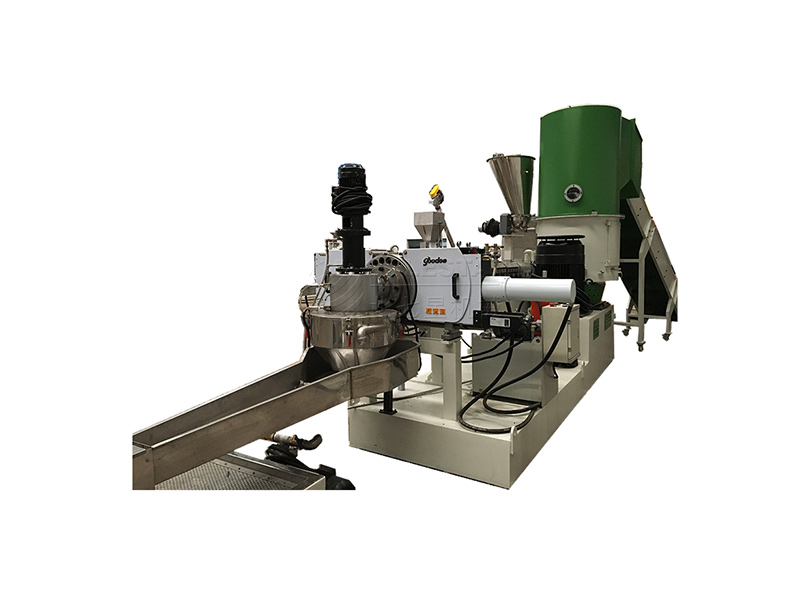

Jeremane Technology Plastic PE PP Granulating Machine

Lintlha

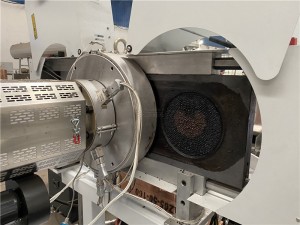

Mochini oa polasetiki oa POLESTAR / Li-Granulator tsa polasetiki tse fanang ka kabo ea mocheso o ts'oanang le homogenization li loketse ho hlahisa li-pellets tsa polasetiki ts'ebetsong ea ho nchafatsa. Mochini oa pelletizer oa polasetiki o fumaneha ka mokhoa o le mong (mochini o le mong feela oa extrusion) le tlhophiso ea mekhahlelo e habeli (mochini o le mong o moholo oa extrusion le mochini o le mong o monyane oa bobeli oa extrusion). Ho kgothaletswa hore o sebelise arraignment e habeli bakeng sa ts'ebetso ea ho tsosolosa ka lebaka la tšilafalo ea thepa ea polasetiki. Ho boetse ho na le likhetho tse fapaneng tsa mahlale a polasetiki a granule pelletizing a fumanehang joalo ka hydraulic assisted screen changer le double-piston screen changer ho etsa bonnete ba hore ha ho na tšitiso nakong ea phetoho ea skrini. Li-gearbox tsa rona tse tšeptjoang li korola ka khutso ho kopanya le ho tsamaisa polasetiki e qhibilihisitsoeng ka har'a moqomo. Sekurufu se entsoeng ka tšepe e hloekisitsoeng ka ho khetheha se tiisa khahlanong le kutu le ho khojoa. Sistimi ea taolo ea mocheso ea PID e nang le moea kapa sistimi e pholileng ea metsi e boloka mocheso o tsitsitseng oa ho sebetsa. "Hot Cut" metsi-ring-ring die face pelletizing le "Cold Cut" mekhoa ea strand pelletizing e fumaneha ho latela khetho ea hau.

Kopo

Lintho tse tala: PE, PP Lifilimi le mekotla

Mochini oa polasetiki oa granulator / mochini oa polasetiki oa pelletizer / mochini oa pelletizer oa polasetiki o nang le agglomerator o ka sebelisoa bakeng sa filimi ea PE / PP kapa mekotla e lohiloeng ea PP le phetisetso e 'ngoe ea parabolic pellet, lisebelisoa li tla hatelloa le ho tiisoa le ho feta ke agglomeration eo ho tla ba bonolo ho e akhela ho tsoa ho extrude, e ka finyellang boholo ba matla a 100-100kg / hora (ho itšetlehile ka litlhoko tsa bareki)

Molemo oa Tlholisano

1. Boemo bo phahameng ba boiketsetso, leka ka hohle ho fokotsa litšenyehelo tsa hau mosebetsing le ho netefatsa bokhoni bo phahameng ba ho sebetsa.

2. Sistimi ea taolo ea botsoalle (PLC e kopantsoeng le taolo e arohaneng mochining o mong le o mong) le Panele ea skrineng ea Touch, e bonolo bakeng sa ts'ebetso, ho beha leihlo le ho emisa tšohanyetso.

3. Likarolo tsohle tse amanang le thepa ea polasetiki le metsi li entsoe ka tšepe ea boleng bo phahameng ba 304; Etsa bonnete ba hore ha ho na tšilafalo ea bobeli ho li-flakes.

4. Siemens contactor, RKC mocheso molaoli

Likarolo tse ka Sehloohong

1. Taolo e itirisang haholo, e bonolo ho basebelisi, e sebetsang hantle haholo, e sireletsa tikoloho le ho baballa matla;

2. Mekhoa e fapaneng ea pelletizing, joalo ka khoele e batang, selikalikoe sa metsi, le ka tlas'a metsi bakeng sa lisebelisoa tse fapaneng tse tala le litlhoko tsa tlhahiso;

3. Sesebelisoa sa ho fetola skrine sa liteishene tse ngata le moralo o ikemetseng oa ho fetola skrineng o ka fokotsa mosebetsi oa matsoho le ho ntlafatsa boiketlo ba ts'ebetso;

4. Mokhahlelo o le mong le oa bobeli, tsamaiso ea ho qeta lintho tse ngata le ho hloekisa e netefatsa boleng bo phahameng le lihlahisoa;

5. E loketse ho sebetsana le lisebelisoa tse fapaneng, hape e ka etsa mochine ka ho khetheha bakeng sa thepa e le 'ngoe kapa thepa e fapaneng, e ka fokotsang litšenyehelo tsa lichelete tsa bareki.

Lintlha tsa Tekheniki

Mohala o le mong oa agglomeration granulation line

| Mohlala | 70 | 100 | 120 | 150 | 180 |

| Sephetho (kg/h) | 70-120 | 200-250 | 300-400 | 500-600 | 700-850 |

| Tšebeliso ea matla (kWh/kg) | 700-850 | ||||

| Matla a maholo (kW) | 37 | 90 | 110 | 132 | 185 |

| Matla a agglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Screw outer diameter (L/D) | 70(33:1) | 100(30-35:1) | 100(30-35:1) | 100(30-35:1) | 180(30-32:1) |

| Vacuum exhaust | Khetho | ||||

| Ho fetola skrine | Tlhophiso e tloaelehileng | ||||

| Metsi-ring granulation | Khetho | ||||

| Cold strand granulation | Khetho | ||||

| Granulation ka tlas'a metsi | Khetho | ||||

Mohala oa granulation oa mekhahlelo e 'meli

| Mohlala | 70+90 | 100+120 | 120+150 | 150+180 | 180+200 |

| Sephetho (kg/h) | 110-180 | 200-300 | 300-450 | 500-650 | 700-850 |

| Tšebeliso ea matla (kWh/kg) | 0.2-0.35 | ||||

| Matla a maholo (kW) | 30+22 | 75+37 | 90+45 | 110+55 | 160+75 |

| Matla a agglomerator(kW) | 30 | 55 | 75 | 110 | 132 |

| Screw outer diameter(L/D) | 70(25+12:1) | 100(25+12:1) | 120(25+12:1) | 150(25+12:1) | 180(25+12:1) |

| Vacuum exhaust | Khetho | ||||

| Ho fetola skrine | 2 lihlopha tsa tlhophiso e tloaelehileng | ||||

| Metsi-ring granulation | Khetho | ||||

| Cold strand granulation | Khetho | ||||

| Granulation ka tlas'a metsi | Khetho | ||||

Lihlopha tsa lihlahisoa

U batla ho kenya Sky ho Moralo oa hau?

Ikopanye le rona kajeno bakeng sa lipuisano tsa moralo.