Mochini oa PET oa Granulating o Phahameng ka ho Fetisisa

Litšobotsi

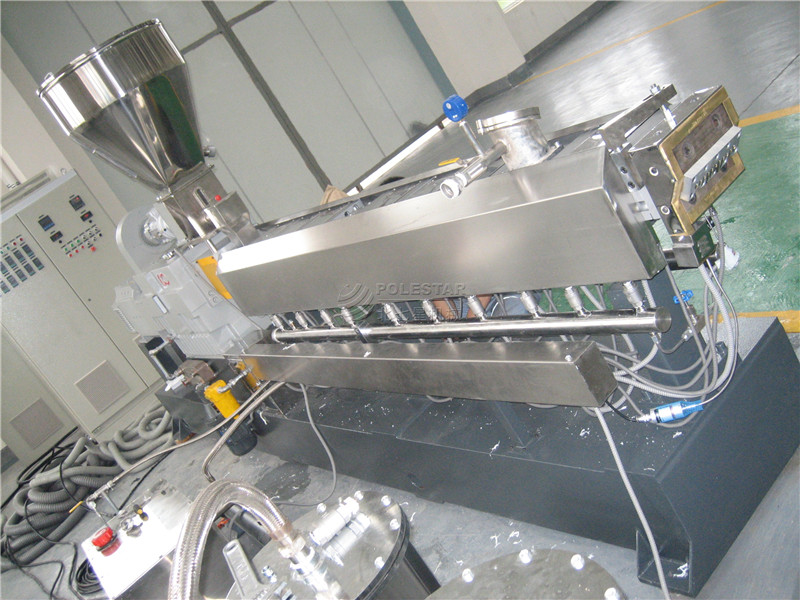

The PET pelletizer haholo-holo e entsoe ka lisebelisoa tse latelang: extruder, hydraulic screen changer, strand cutting hlobo, cooling conveyor, dryer, cutter, fan blowing system (ho fepa le ho omisa), joalo-joalo Sebelisa parallel twin screw extruder ho ba le taolo e nepahetseng ea mocheso. , tlhahiso e phahameng e nang le tšebeliso e tlaase ea matla.

Kopo

Mochini oa pelletizing oa pet o sebelisetsoa ho etsa li-flakes tsa polasetiki tsa PET ka pellet kapa granule.Twin screw extruder recycling & pelletizing system e sebelisoa ho lisebelisoa tsa litšila, tse hlokang ts'ebetso e phahameng ea ts'ebetso ea melting, volatilization, filtering joalo-joalo.

Phallo ea Ts'ebetso

Screw feeder ( KA KHETHA)→ Qobella sekoahelo → Sekoahelo sa "parallel twin screw extruder" →Sehlahisoa se hloekisang ka metsi→ Hlooho ea hlobo → tanka ea ho pholisa metsi → Sekha se tloaelehileng sa polasetiki → Sehlahisoa se qetile ho paka.

Tlhaloso e qaqileng ea Ntho ka 'ngoe

1. Screw Feeder: fetisa likhechana tsa polasetiki mochining o moholo.

2. Matla a fepa: thepa ea ho fepa ho extruder ka lebelo le etselitsoeng, lebelo le ka fetoloa.

3. Parallel twin screw extruder: thepa ea polasetiki le khase e khathatsang.

4. Sistimi ea phapanyetsano e phahameng ea Net le Die-head: ho se hloeke ha lintho tse sefang, ho etsa hore tlhahiso e be e tsitsitseng.

5. Tanka ea metsi: ho pholisa li-noodle tsa PET.

6. Seha se tloaelehileng sa polasetiki: khaola li-noodle tsa PET ka li-granuel.

Molemo oa Tlholisano

1. Taolo ea PLC e ikemetseng

2. Ka taolo ea mocheso oa motho ka mong

3. Ts'ebetso e bonolo le ts'ebetso e tsitsitseng

4. Ts'ireletso ea tikoloho e sebetsang hantle haholo le ho boloka matla

Lintlha tsa Tekheniki

| Extruder | TSK35 | TSK50 | TSK60 | TSK65 | TSK75 | TSK95 |

| L/D(mm) | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 | 24-56 |

| Lebelo le Leholo(rpm) | 600 | 500 | 300-500 | 400-500 | 400-500 | 300-400 |

| Matla a Motlakase(kw) | 11-18.5 | 22-37 | 37-55 | 45-75 | 90-160 | 185-250 |

| Matla a Heater(kw) | 16 | 24 | 30 | 34 | 45 | 60 |

| Sephetho se Phahameng(kg/h) | 20-80 | 50-200 | 80-300 | 100-350 | 200-500 | 700-1200 |

Lihlopha tsa lihlahisoa

U batla ho eketsa Sky ho Desing ea hau?

Ikopanye le rona kajeno bakeng sa lipuisano tsa moralo.